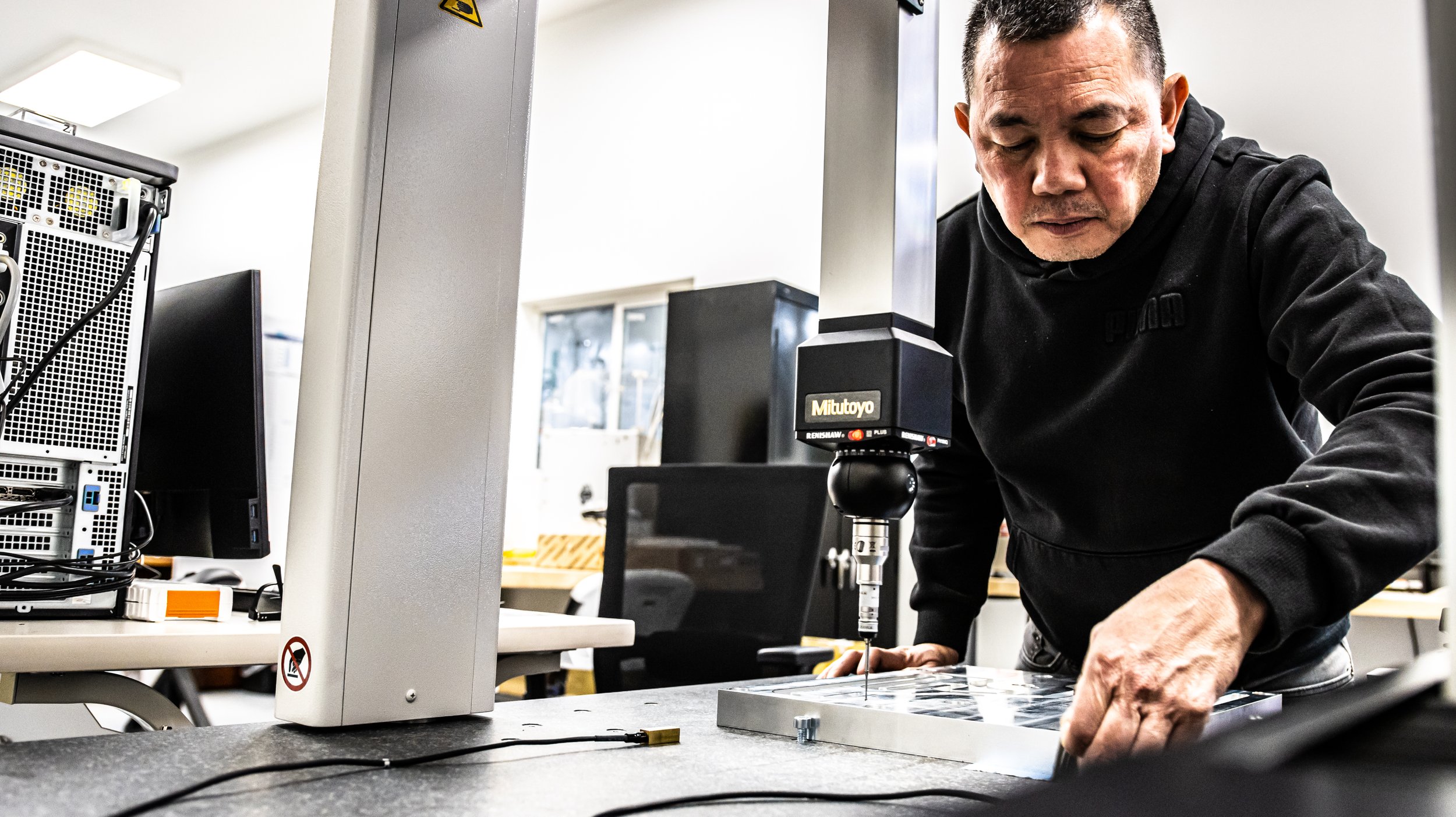

Mechanical part Design & Prototyping Services

We help cut costs and improve part specifications through design for manufacturability

Our goal is to find success in helping you succeed in your supply chain goals. One of the ways we do that is by partnering with design engineers and mechanical engineers on the front end of projects. We help review products and look for cost drivers and deficiencies in the part design to help improve the the effectiveness of parts and improve the overall project costs.

Once we review part design we can also assist with prototypes. This allows for design changes and proper testing to assure you are happy with the products. After the prototypes are made and proven we then have everything we need to enter into production and have the ability to manufacture repeatable parts at scale.

WHAT IS Design fOR mANUFACTURING (DFM)?

DFM stands for Design for Manufacturing and is an engineering practice for designing products that can be produced more efficiently at less cost. DFM will allow potential problems to be addressed during the design phase which is the least expensive phase to implement changes.

GrovTec Machining works closely with many of its clients in the Design for manufacturing stage to address potential challenges which may be present in the initial product design. Some areas of focus may include Product Design, Material Types, complex geometry, and allowable tolerances. All of these factors, when optimized can lead to the overall reduction of manufacturing costs as well as increased manufacturing efficiency.

The goal is to work side by side with our clients to provide any insights and/or recommendations while we transition a project from the design to reality.